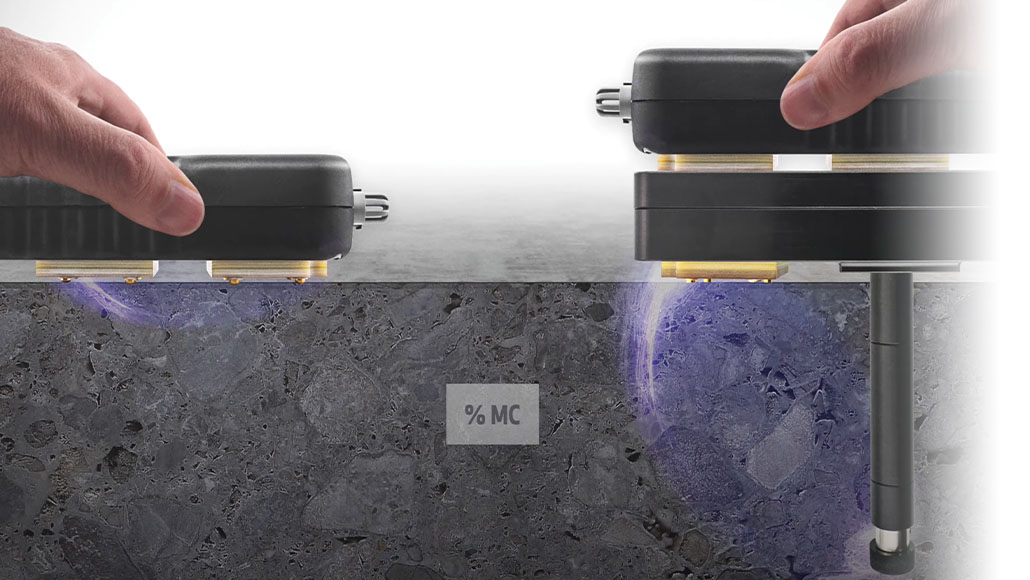

Non-destructive impedance testing of concrete

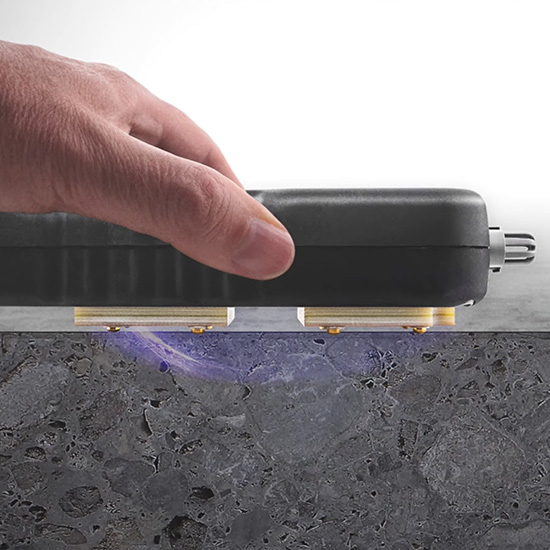

The Tramex non-destructive impedance test measures the percentage moisture content in the top ¾ inch (20mm) of the slab, using either of the Tramex Concrete Moisture Encounters CME5 or CMEX5.

These concrete moisture meters instantly determine precise quantitative measurement of moisture content % in concrete, using Gravimetric testing as a baseline.

Although the ASTM F2659 standard does not specify the use of a quantitative moisture meter, conducting the impedance test with a calibrated, quantitative concrete moisture meter will provide accurate moisture content % readings, as opposed to a comparative meter which only provides a relative indication.

Using a quantitative meter can prove essential as many flooring manufacturers' guidelines require actual moisture content % (%MC) readings.

learn more