Step 1: Check Ambient conditions

When arriving on site, take note of the ambient temperature, ambient relative humidity and dew point conditions. These readings will be needed for reference in later steps.

Ensure that the test area is in ‘in service’ conditions, which means that the temperature should be between 65-85℉ or 18-30℃, and relative humidity readings between 40-60 %RH.

As concrete is generally 1-2 degrees cooler than the air temperature, be aware of any potential condensation in the top layer of the slab, which may be caused by moisture moving from hot to cold.

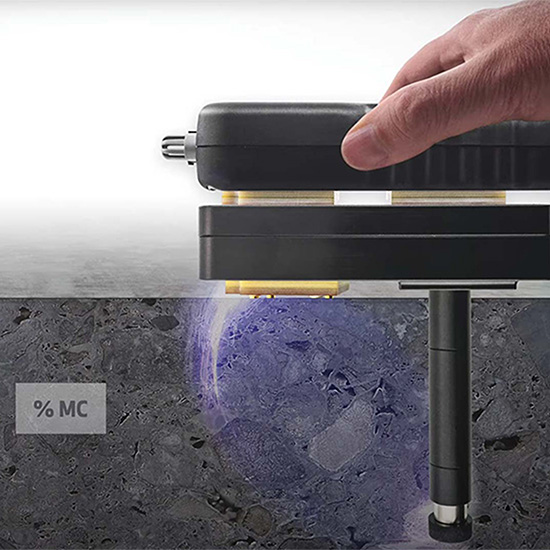

These tests can be performed using either the Concrete Moisture Encounter X5 - CMEX5 with built-in hygrometer or with the IRT2DP.